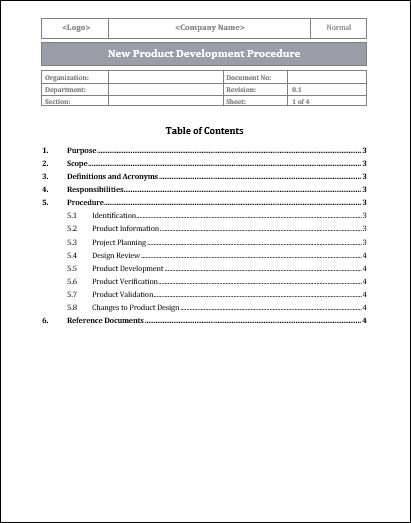

ISO 9001 New Product Design and Development Procedure

The New Product Design and Development Procedure Template for ISO 9001 helps organizations establish a systematic and structured approach to developing new products. It covers all aspects of the process and provides step-by-step guidance with instructions, checklists, and forms. By using this template, organizations can improve product design and development, reduce development time, increase customer satisfaction, and comply with ISO 9001 requirements.

It can be customized to fit different organization's needs and establishes a consistent and repeatable process. Overall, it provides a framework for effectively managing product design and development to achieve business success.

Understanding the importance of product design and development

ISO 9001 is an internationally recognized quality management standard that sets out the criteria for a quality management system. One of the key requirements of ISO 9001 is the establishment and maintenance of a product design and development procedure.

The product design and development procedure is important for several reasons:

- Ensures customer satisfaction: By following a systematic design and development procedure, organizations can ensure that products meet customer requirements and expectations. This includes gathering customer input, defining product specifications, and conducting design reviews to ensure that the product meets the desired quality standards.

- Reduces risks: The product design and development procedure helps organizations identify and mitigate potential risks associated with product design. This includes identifying and addressing safety, regulatory, and performance risks that may arise during the design and development process.

- Improves efficiency: A well-defined product design and development procedure helps streamline the design process, reducing time and resource wastage. By following a systematic approach, organizations can identify inefficiencies in their design process and implement improvements to enhance productivity and reduce costs.

- Facilitates continuous improvement: ISO 9001 encourages organizations to continually improve their processes. The product design and development procedure provides a framework for organizations to collect feedback and data on product performance, identify areas for improvement, and implement necessary changes to enhance product quality.

- Enhances product quality: A robust product design and development procedure ensures that products are designed and developed in accordance with best practices and industry standards. This helps organizations deliver high-quality products that meet customer requirements and comply with relevant regulations.

- Builds customer trust: By adhering to ISO 9001 standards and following a rigorous product design and development procedure, organizations demonstrate their commitment to delivering quality products. This builds customer trust and confidence, leading to increased customer loyalty and repeat business.

Overall, the product design and development procedure plays a crucial role in ensuring customer satisfaction, reducing risks, improving efficiency, facilitating continuous improvement, enhancing product quality, and building customer trust. By implementing and maintaining this procedure, organizations can align their product design and development processes with the requirements of ISO 9001, leading to improved performance and competitiveness in the marketplace.

Key components of a successful product design and development procedure

- Clear and well-defined product requirements: The template should include a systematic approach to identify and document product requirements based on customer needs and expectations.

- Design planning: The template should outline the process for developing a design plan that includes the scope of the project, resources required, tasks, timelines, and responsibilities.

- Conceptual design: The template should provide guidance on how to create and evaluate various design concepts based on the established requirements.

- Detailed design: The template should include guidelines for creating detailed design specifications, considering factors such as materials, manufacturing processes, and cost.

- Design validation and verification: The template should outline the procedures for conducting design tests and evaluations to ensure that the product meets the specified requirements and performance criteria.

- Design review: The template should include a process for periodically reviewing the design to identify and address any potential issues or improvements.

- Design changes and modifications: The template should include procedures for managing design changes, including assessing the impact of changes, obtaining necessary approvals, and updating relevant documentation.

- Risk management: The template should incorporate risk management principles and techniques to identify and mitigate potential risks associated with the design and development process.

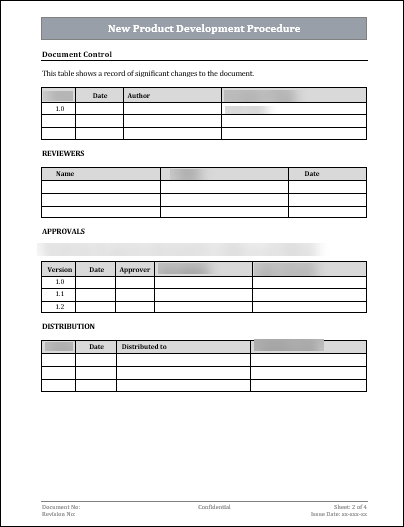

- Documentation control: The template should include guidelines for maintaining accurate and up-to-date documentation throughout the design and development process.

- Customer feedback and input: The template should include mechanisms for obtaining customer feedback and incorporating it into the product design and development process.

- Continuous improvement: The template should include provisions for ongoing monitoring and evaluation of the design and development process to identify opportunities for improvement and implement corrective actions.

- Regulatory compliance: The template should ensure that the design and development process adheres to all applicable regulations, standards, and legal requirements.

Benefits of product design and development in line with ISO 9001 requirements

There are several benefits of implementing a product design and development procedure in line with ISO 9001 requirements. Some of the key benefits include:

- Improved product quality: ISO 9001 emphasizes the need for a systematic approach to product design and development, which leads to improved product quality. Following the procedure ensures that all necessary steps, such as customer requirements analysis, risk assessment, and validation, are carried out effectively, resulting in high-quality products.

- Increased customer satisfaction: ISO 9001 focuses on meeting customer requirements and expectations. By implementing a product design and development procedure in line with ISO 9001, organizations are better able to understand customer needs and develop products that meet those needs. This leads to increased customer satisfaction and loyalty.

- Reduction of errors and rework: The product design and development procedure outlined in ISO 9001 helps identify and mitigate potential risks and errors early in the process. By addressing these issues before the product enters production, organizations can minimize the occurrence of defects, errors, and rework, saving time and resources.

- Enhanced control and traceability: ISO 9001 requires organizations to establish document control and record-keeping systems. Implementing a product design and development procedure in line with ISO 9001 ensures that all design-related documentation, such as design specifications, drawings, and change requests, are properly controlled and maintained. This enables better traceability and facilitates effective communication between different functions involved in product development.

- Continuous improvement: ISO 9001 promotes a culture of continuous improvement. The product design and development procedure encourages organizations to monitor and evaluate design effectiveness, identify areas for improvement, and implement necessary corrective actions. By continuously improving the product design and development process, organizations can enhance their competitiveness and stay ahead in the market.

- Compliance with international standards: ISO 9001 is an internationally recognized standard for quality management systems. By implementing a product design and development procedure in line with ISO 9001 requirements, organizations demonstrate their commitment to quality and compliance with international standards. This can help build trust and confidence among customers, suppliers, and other stakeholders.

Conclusion:

It is a rigorous process that ensures quality and consistency in the final product. This certification requires companies to follow a structured approach in all stages of product design and development, including planning, design verification, and validation.

Additionally, it emphasizes the importance of customer requirements and feedback in the design process, ensuring that the final product meets or exceeds customer expectations. Overall, obtaining ISO 9001 certification for product design and development is a valuable achievement that demonstrates a company's commitment to quality and customer satisfaction.